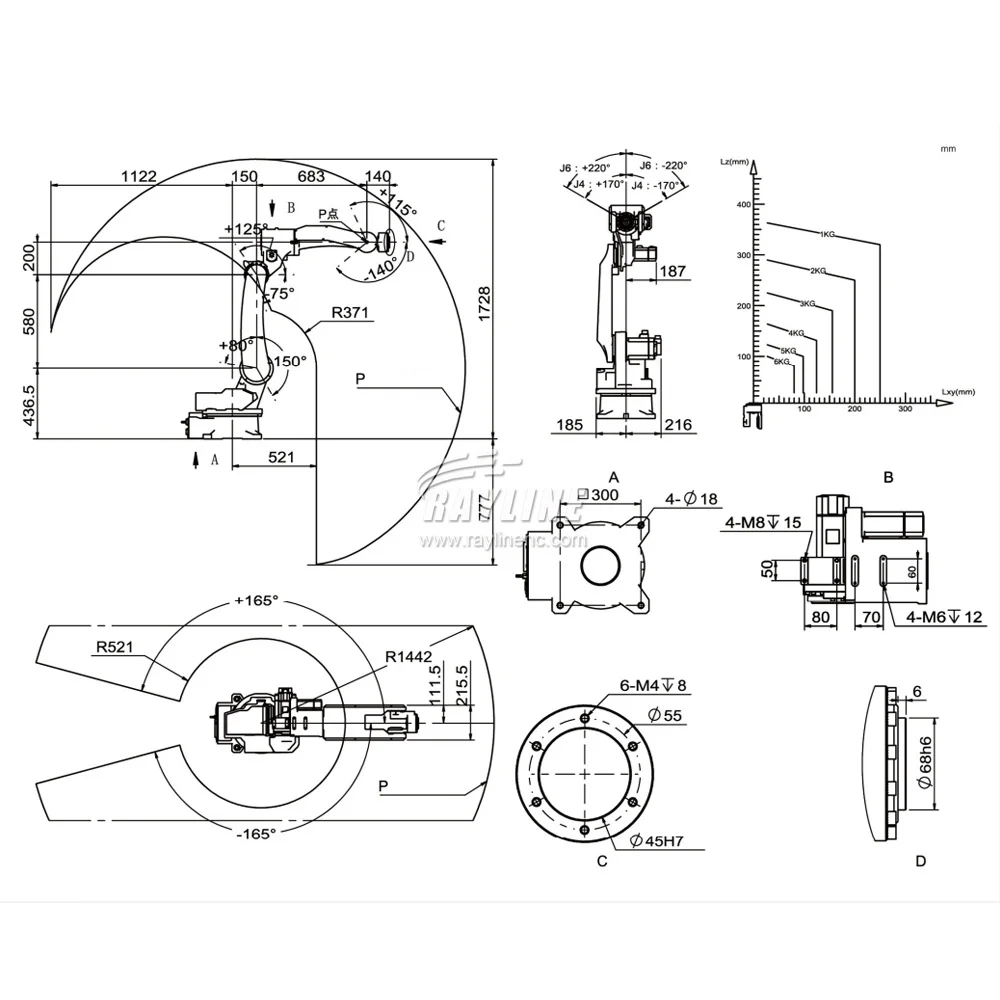

Maximum working radius 1500mm

Load: 6kg

Repeat positioning accuracy: ±0.03

Power capacity 3.7KVA

Main body weight 170kg

Protection level IP54/IP65

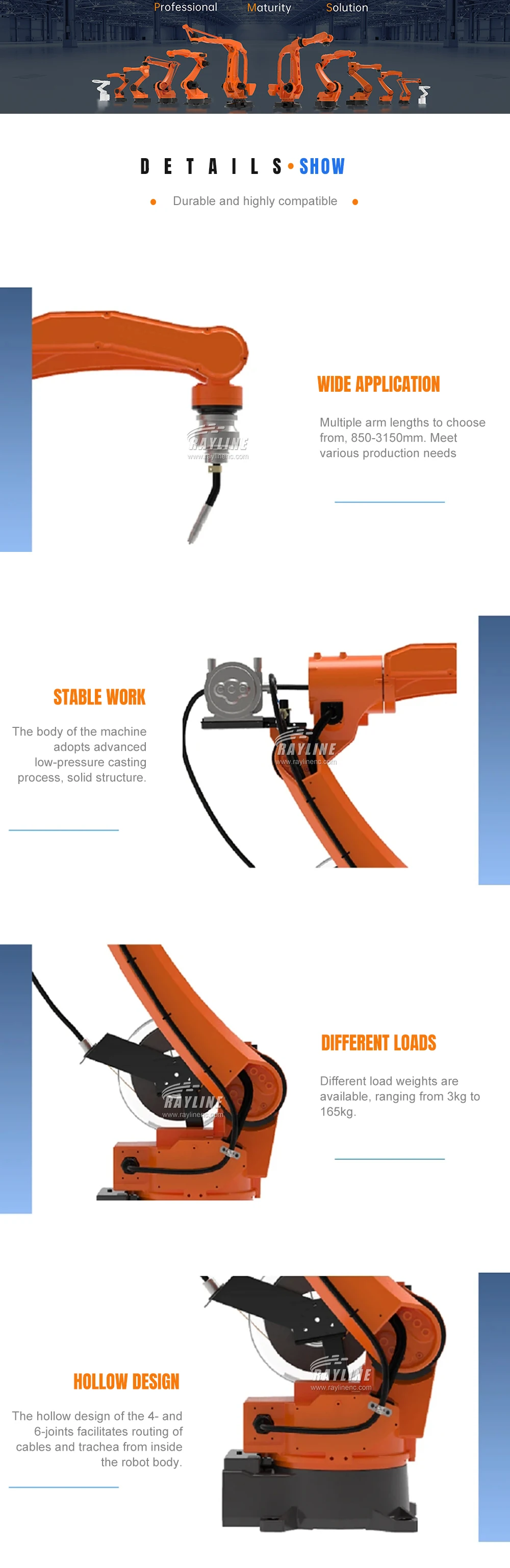

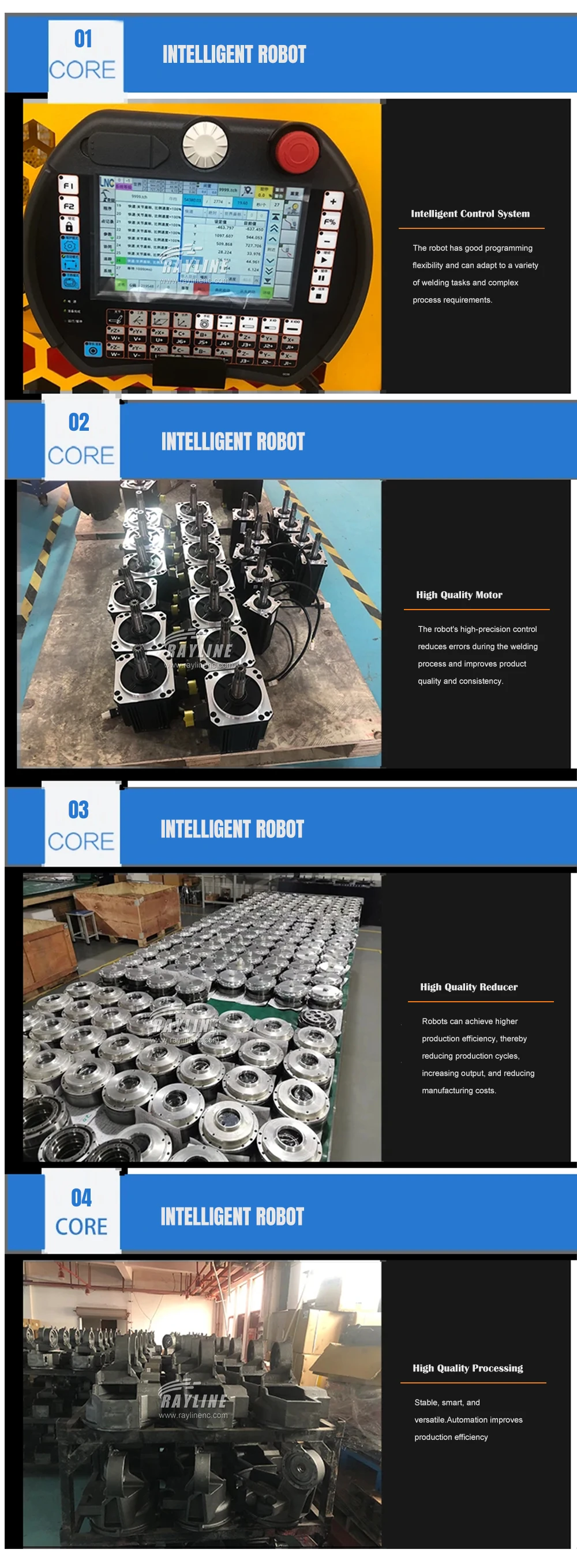

YH series welding robots are industrial robots engaged in welding (including cutting and spraying). Industrial robots belong to standard welding robots. Industrial robots are multi-purpose, reprogrammable automatic control manipulators used in the field of industrial automation. In order to adapt to different uses, the mechanical interface of the last axis of the robot is usually a connecting flange, which can be connected to different tools or end effectors. The YH series welding robot is to install welding tongs or welding (cutting) guns on the end axis flange of the industrial robot, so that it can perform welding, cutting or thermal spraying.

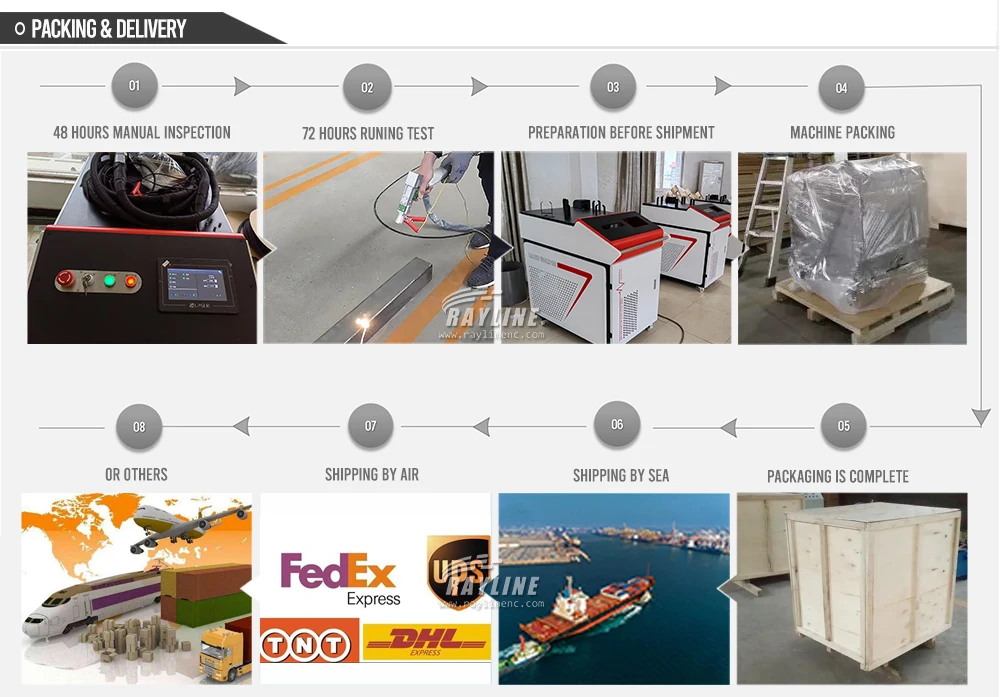

The welding robot mainly consists of two parts: the robot and the welding equipment. The robot consists of the robot body and the control cabinet (hardware and software). The welding equipment, taking arc welding and spot welding as examples, consists of welding power supply (including its control system), wire feeder (arc welding), welding gun (tongs) and other parts. Intelligent robots should also have sensing systems, such as laser or camera sensors and their control devices.

Advantages

1) Stabilize and improve welding quality, and reflect welding quality in numerical form;

2) Improve labor productivity;

3) Improve workers’ labor intensity and allow them to work in harmful environments;

4) Reduce the requirements for workers’ operating skills;

5) Shorten the preparation period for product upgrades and reduce corresponding equipment investment.

About DC welding machine

1. Ithas three welding modes: low splashing, fast spot welding and constant

pressure

2. Ultra-low spatter welding of carbon

steel can be achieved from 1 to 3mm. The welding spatter is reduced by 60%;

3. The heat input is reduced by 10%~20%,

the welding of thin plates is easy to control, and the deformation is small;

4. The whole digital system can realize the

precise control of droplet transition and achieve continuous and stable welding

quality;

5. Soft switching inverter technology,

which can improve the reliability of the whole machine and save energy;

6. Full digital high precision wire feeding

control system, two drive and two from with encoder full digital control wire

feeding device, even if the power voltage, wire feeding resistance and other

external factors change, it can still ensure the stability of wire feeding.

| Model | NBC-350RL |

| Rated Input Voltage/frequency (V/Hz) |

Three phase 380±10%/50 |

| Rated Input Capacity (KVA) |

14 |

| Rated Input Current (A) | 21 |

| Rated Output Voltage (V) |

31.5 |

| Rated Load Duration Rate (%) |

60 |

| Output No-load Voltage (V) |

96 |

| Output Current/voltage Range (A/N) |

60/17~350/31.5 |

| Wire Diameter (mm) | 0.8、1.0、1.2 |

| Wire Feeding type | Pulling the thread |

| Gas Fflow (L/min) | 15~20 |

| Welding Torch Cooling Method | air-cool |

| Protection Level of the Enclosure |

IP23 |

| Insulation grade | H |

| External dimensions L x W x H (cm) |

66×32×56 |

| Weight (Kg) | 55 |

| Color | Nbc-350Rl, Robot |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.